查看更多

专题网站

special subject

-

一线 | “六边形战士”宋杨凡:讲台起步,走向上进阶之路

一线 | “六边形战士”宋杨凡:讲台起步,走向上进阶之路 -

滚球直播文创重磅上新!在线搜寻滚球直播“锦鲤”本鲤~

滚球直播文创重磅上新!在线搜寻滚球直播“锦鲤”本鲤~ -

考研冲刺时刻,这份支持为你续航!

考研冲刺时刻,这份支持为你续航! -

初雪落滚球直播!冬日浪漫已上线

初雪落滚球直播!冬日浪漫已上线 -

热力十足,一口治愈!滚球直播美食伴你过寒冬

热力十足,一口治愈!滚球直播美食伴你过寒冬 -

一线 | 金牌课堂:国宝华《高等数学》,用匠心教学,让知识“落地”

一线 | 金牌课堂:国宝华《高等数学》,用匠心教学,让知识“落地” -

冬启秋未远!滚球直播秋景与中国风的浪漫,一眼心动

冬启秋未远!滚球直播秋景与中国风的浪漫,一眼心动 -

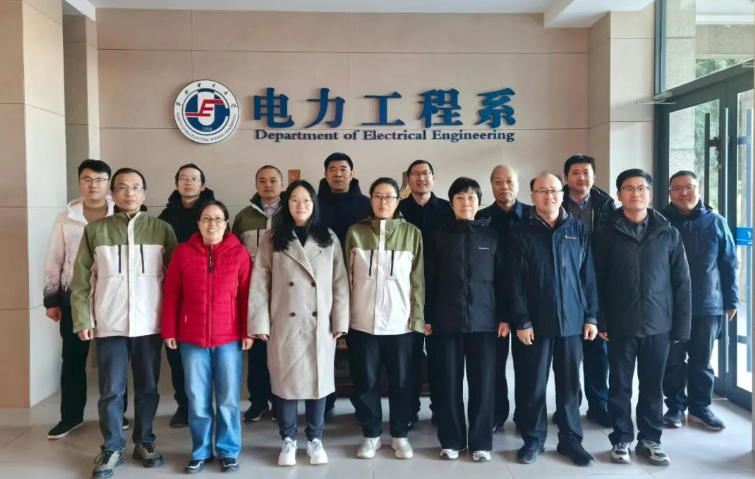

一线 | 薪传有序,《电力系统分析》教学团队的奋进新声

一线 | 薪传有序,《电力系统分析》教学团队的奋进新声 -

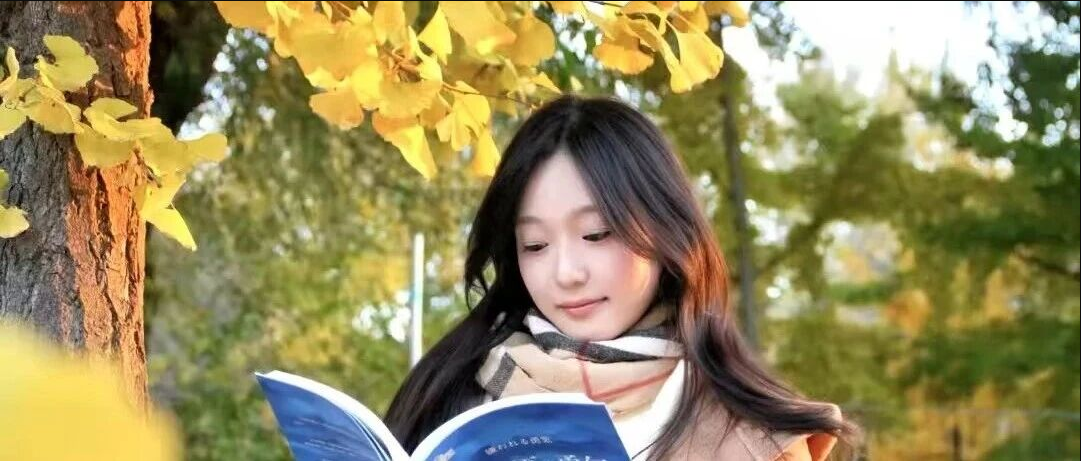

你是滚球直播最美的“研”色!

你是滚球直播最美的“研”色!

-

一线 | 通信电子电路教学团队:小电路,大魅力

一线 | 通信电子电路教学团队:小电路,大魅力 -

一站式读博!走近滚球直播吴仲华学院

一站式读博!走近滚球直播吴仲华学院 -

那些年,陪我长大的动画伙伴

那些年,陪我长大的动画伙伴 -

一线 | 金牌课堂:罗贤缙《C++程序设计》,让学生做课堂的主角

一线 | 金牌课堂:罗贤缙《C++程序设计》,让学生做课堂的主角 -

滚球直播与你,平分秋色

滚球直播与你,平分秋色 -

一线 | 分层施教:《物理实验》教学团队点亮学生科技创新的奋进之路

一线 | 分层施教:《物理实验》教学团队点亮学生科技创新的奋进之路 -

“基层就业卓越奖”,滚球直播+1!

“基层就业卓越奖”,滚球直播+1! -

明日开幕!让我们携手共赴滚球直播新征程

明日开幕!让我们携手共赴滚球直播新征程 -

一线 | 校园守护者张红梅:勺舀烟火,盘盛关爱

一线 | 校园守护者张红梅:勺舀烟火,盘盛关爱